Labeling machinery is used in electronics, pharmaceutical, packaging and shipping, agriculture, food and beverage, chemical, medical, and many more industries. There are many different labeling machines and the industry is continuing to grow. It is important to find the differences in the wide array of labeling machinery. Knowing the ins and outs can save you time and money in the long run.

Below is a list of different kinds of labeling machinery:

Automatic applicators typically are used for high volumes of labeling for containers and other products. As the conveyor moves the product or container into position, a photo eye senses it and activates the application of the label.

Barcode labeling makes the production and application of encoded tags. This allows manufacturers to get a lot of information about a specific product or container without the use of large or cumbersome labels.

Label dispensers are used in with label printers and applicators to facilitate the easy removal of the tags, tickets and stickers from the protective backing on which they are printed. Dispensers only partially remove the backing which is then fully removed by hand or other automated device.

Bottle labelers make up a large portion of all labeling machines as they are utilized in several industrial and commercial applications for both informative and brand labeling of bottles, jars and vials of varying shapes and sizes.

Label printers are specially designed machines used to print labels or adhesive stamps on such variable materials as tape, ribbon, paper, metal, plastic, film, ceramics or fabric.

Label makers refer to stand alone labeling systems that simplify the production of tags, tickets, stickers and seals for ease of use and customization in many home and office environments. Although the term is more often applied to small hand-held devices, larger labeling machinery may also be referred to as such.

Print and apply labelers print labels when needed and apply them. An operator positions the product and activates the unit for label application by depressing a foot switch or a proximity switch, palm button or hot eyes; the operator then removes the product and continues the sequence again.

Cardboard Tubes

Cardboard Tubes Carrying Cases

Carrying Cases Contract Packaging

Contract Packaging Corrugated Boxes

Corrugated Boxes Dot Peening Machines

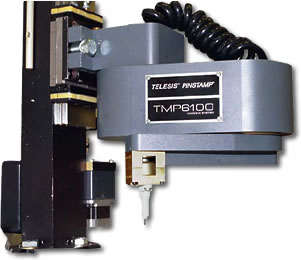

Dot Peening Machines Labeling Machinery

Labeling Machinery Marking Machinery

Marking Machinery Packaging Equipment

Packaging Equipment Palletizers

Palletizers Plastic Bags

Plastic Bags Sewing Contractors

Sewing Contractors Tape Suppliers

Tape Suppliers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services