Labeling machinery is a critical tool in many industries, allowing businesses to label their products with accuracy, consistency, and efficiency. This article will explore the components of labeling machinery, types of labeling machinery, considerations regarding labeling machinery, its benefits for businesses, and its various applications. Read More…

JN White is an ISO 9001:2015 and ITAR-certified manufacturer of labeling machinery, graphic overlays, and custom labels. We handle projects of a variety of sizes, and we have the expertise to translate what our customers need into high-quality, high-precision outcomes.

BW Packaging is a leading label application manufacturer creating equipment for automotive, food & beverage, commercial, consumer, and pharmaceutical industries, to name a few. We have a dependable support program, from installation to maintenance and replacement parts. We partner with our customers through the entire process, from planning to production. Contact us today.

We offer top of the line label machines to suit the needs of our customers. We are the largest manufacturer of labeling equipment in the country, and we have everything our customers can think of. We can customize our products to suit your unique needs and requirements. We believe in offering the best technologies and techniques to all customers. Contact us to learn more!

We offer labelers and labeling machinery: hot melt glue labeling systems, pressure sensitive labeling machines and shrink sleeve labeling machines. Since 1989, Accutek Packaging Equipment has designed/manufactured bottling and packaging machinery. We can customize to fit any application.

Label-Aire has been producing top of the line label machines for nearly fifty years. We offer the easiest, most effective labeling solutions around and we have dependable customer service representatives and a highly skilled team of technicians. We pride ourselves on being the best in terms of quality and service. Your satisfaction is guaranteed, so put us to work for you today!

More Labeling Machinery Manufacturers

Labeling machinery is a cornerstone of modern packaging and manufacturing operations, providing automated labeling solutions that ensure efficiency, accuracy, and consistency across a wide array of industries. Whether you are seeking to streamline product identification, improve compliance, or enhance brand visibility, investing in the right labeling machinery can have a transformative impact on your business. In this comprehensive guide, we explore the essential components of labeling equipment, the various types of labeling machines available, key selection criteria, core benefits, and a deep dive into use cases spanning leading industries. Use this resource to inform your research, compare manufacturers, and identify the solution that best fits your unique requirements.

Components of Labeling Machinery

Understanding the core components of labeling machinery is crucial for selecting a system that meets your operational needs. Standard labeling machine components include:

- Labeling Applicator: The applicator is responsible for precisely applying the label to each product or package, ensuring consistent placement and adhesion.

- Conveyor System: This mechanism transports products through the labeling process, allowing for seamless integration with upstream and downstream packaging equipment such as filling, capping, or sealing machines.

- Labeling Head: The labeling head holds and dispenses labels, operating in coordination with sensors and control systems to maintain accuracy at high speeds.

- Control System: The brain of the labeling machine, the control system manages timing, speed, and synchronization of all moving parts. Modern systems often feature programmable logic controllers (PLCs) and touchscreen human-machine interfaces (HMIs) for intuitive operation and real-time monitoring.

- Power Source: Most labeling machinery is powered electrically, but some systems may also use pneumatic or hydraulic components for specific tasks, depending on the application.

Advanced labeling machinery may include additional features such as integrated printers for variable data printing, inspection cameras for quality control, and automated label reel changers to reduce downtime in high-volume environments. Are you wondering which components are most critical for your specific labeling application? Contact our experts for a tailored consultation.

Types of Labeling Machinery

There is a diverse range of labeling machine types available, each engineered to handle different product shapes, packaging materials, and application requirements. Here is an overview of the most common labeling machinery types and their typical use cases:

Pressure-Sensitive Labeling Machines

Pressure-sensitive labeling machines are among the most versatile and widely used systems in the packaging industry. Utilizing pressure-sensitive adhesives (PSA), these machines apply pre-cut labels to a variety of product surfaces with minimal setup. They are exceptionally popular in industries such as food and beverage, pharmaceuticals, cosmetics, and chemicals where fast changeovers and precise placement are priorities. Whether you need to apply labels to bottles, jars, boxes, or pouches, pressure-sensitive machines offer flexibility and scalability for both small and large production runs.

Sleeve Labeling Machines

Sleeve labeling machines, also known as shrink sleeve or stretch sleeve applicators, are designed for full-body labeling. By applying a plastic sleeve over the product and then shrinking it with heat, these systems deliver 360-degree coverage, making them ideal for products that require tamper-evident seals or high-impact graphics. Industries such as beverages, personal care, and household cleaning products frequently rely on sleeve labeling for branding and compliance. Their ability to conform to complex shapes and sizes makes sleeve labeling machinery a go-to solution for innovative packaging designs. Need tamper-evident or promotional packaging? Consider the advantages of shrink sleeve technology.

Hot Melt Labeling Machines

Hot melt labeling machines use thermoplastic adhesives to secure labels, offering exceptional bond strength even in challenging environments. These systems are especially prevalent in the food and beverage sector for labeling glass, PET, and HDPE bottles or jars—where moisture resistance and label longevity are critical. Hot melt adhesives set rapidly, enabling high-speed operation and reduced label slippage. If your production facility faces high humidity or condensation, hot melt labeling can ensure your branding stays intact from the production line to the retail shelf.

Cold Glue Labeling Machines

Cold glue labeling machines utilize water-based adhesives to affix paper labels to products. Known for their reliability and cost-effectiveness, cold glue systems are preferred in applications where label appearance and eco-friendliness are important, such as wine, spirits, and pharmaceutical packaging. These machines are highly adaptable to different label shapes and materials, delivering crisp, clean application with minimal waste. Looking for eco-friendly labeling solutions? Cold glue technology offers a sustainable alternative to pressure-sensitive labels.

Print and Apply Labeling Machines

Print and apply labeling machines combine real-time printing and label application in a single automated process. These systems are indispensable for operations requiring variable data printing—such as barcodes, batch numbers, expiration dates, and shipping information. Frequently used in logistics, warehousing, and e-commerce fulfillment centers, print and apply machines boost traceability and compliance while reducing manual labor. Interested in improving inventory management and traceability? Discover the benefits of print and apply automation.

RFID Labeling Machines

RFID labeling machines integrate radio-frequency identification (RFID) technology into product labels, enabling automated tracking, anti-counterfeiting, and enhanced supply chain transparency. These advanced systems are widely adopted in industries such as logistics, automotive, healthcare, and aviation for tracking assets, managing inventory, and ensuring regulatory compliance. By combining RFID with traditional labeling, businesses can unlock new levels of efficiency in their operations. Want to future-proof your supply chain? Learn more about RFID-enabled labeling solutions.

Specialty Labeling Machinery

Beyond the primary categories, there are also specialty labeling machines tailored for niche applications, including:

- Wrap-around Labelers: Ideal for cylindrical products such as bottles and cans.

- Top and Bottom Labelers: Designed for flat packages, trays, and clamshells.

- Corners and Tamper-Evident Labelers: For security labeling on pharmaceutical and food packages.

- Laser Marking Systems: For permanent, non-contact coding and serialization.

Considerations Regarding Labeling Machinery

When investing in labeling machinery, it is vital to weigh various decision factors to ensure optimal performance and return on investment (ROI). Here are the key considerations:

- Initial Investment: High-quality labeling systems represent a significant capital expenditure, but their long-term benefits often justify the upfront cost. Businesses should evaluate the total cost of ownership, including installation, integration, and depreciation.

- Maintenance and Downtime: Regular preventive maintenance is necessary to maximize uptime and prevent costly breakdowns. Consider the availability of spare parts, technical support, and service contracts when choosing a manufacturer.

- Operator Training: Proper training minimizes user errors and ensures safe, efficient operation. Look for manufacturers that provide robust onboarding and technical training resources.

- Labeling Errors: Incorrect setup or poor maintenance can lead to misapplied or missing labels, potentially resulting in product recalls, regulatory fines, or brand damage. Automated inspection and reject systems can help mitigate this risk.

- Scalability: As production demands grow, your labeling machinery should be capable of scaling—either through modular upgrades or increased automation.

- Compatibility: Ensure the chosen machine integrates seamlessly with your existing packaging line and ERP or MES (Manufacturing Execution Systems) software.

Benefits of Labeling Machinery

Labeling machinery delivers a wide spectrum of business advantages that extend beyond simple automation:

- Precision and Consistency: Automated labeling ensures uniform application, reducing the likelihood of misaligned or wrinkled labels that could compromise brand image or regulatory compliance.

- Increased Throughput: High-speed labeling machines can process hundreds or thousands of products per hour, dramatically boosting productivity compared to manual methods.

- Lower Labor Costs: Automation reduces dependence on manual labor, lowering operational expenses and freeing staff for higher-value tasks.

- Improved Compliance: Accurate, machine-applied labels help businesses meet industry-specific regulatory requirements, such as FDA, EU, or GHS labeling standards.

- Greater Flexibility: Modern labeling machinery supports rapid changeovers and customization, allowing manufacturers to switch between product SKUs with minimal downtime.

- Enhanced Traceability: Integrated printers and RFID technology enable end-to-end product tracking and serialization for better supply chain visibility.

- Reduced Waste: Automated systems minimize label waste and product rejects, supporting sustainability goals and reducing material costs.

Applications of Labeling Machinery

Labeling machinery is indispensable across an array of sectors, each with unique requirements for product identification, compliance, and branding. Below, we outline key industries and how they leverage labeling automation to drive value:

Automotive Industry

In the automotive sector, labeling machinery is used for marking parts, assemblies, and aftermarket components with identification codes, barcodes, lot numbers, and safety warnings. Durable labels are critical for traceability, quality control, and compliance with industry regulations. Automotive labeling machines often integrate with robotics and vision systems for high-precision placement.

Agriculture Industry

Labeling machinery helps agricultural producers and processors label fresh produce, packaged foods, seeds, and fertilizers with essential information such as origin, nutritional values, and branding. Automated labeling supports food safety traceability and efficient supply chain management.

Aerospace Industry

In aerospace, labeling machinery ensures that every component, from fasteners to avionics, is marked with serial numbers, regulatory information, and safety instructions. Given the stringent quality and traceability standards in aviation, aerospace labeling systems often include laser marking or RFID tagging capabilities.

Clothing Industry

The clothing and apparel sector employs labeling machinery to affix care instructions, fabric content, size, and branding to garments. Automated systems support high-speed application on tags, labels, and packaging for retail distribution.

Consumer Goods Industry

For personal care, household, and cleaning products, labeling machinery applies product information, branding, safety warnings, and promotional graphics. Modern systems enable rapid changeovers for multiple SKUs and support compliance with international labeling regulations.

Packaging Industry

Labeling is integral to the packaging industry, with machines applying barcodes, shipping labels, branding, and compliance information to cartons, cases, bags, and trays. Integrated print-and-apply systems streamline warehouse operations and logistics, enabling real-time inventory management.

Wine Industry

The wine industry relies on labeling machinery for bottle labeling, applying front and back labels, neck bands, and government-mandated health warnings. Precision and aesthetic quality are critical for brand differentiation and regulatory compliance.

Medical Industry

Labeling machinery is vital for labeling pharmaceuticals, medical devices, and diagnostic kits with dosage information, lot numbers, expiration dates, and regulatory symbols. Accurate labeling is essential for patient safety and compliance with FDA, GMP, and UDI requirements.

Nutraceutical Industry

In the nutraceuticals sector, labeling machinery applies ingredient lists, dosage recommendations, branding, and legal disclaimers to bottles, jars, and blister packs. Automated systems help manufacturers meet evolving regulatory demands and consumer transparency expectations.

Pet Food Industry

Automated labeling is used in the pet food industry to apply nutritional details, feeding guidelines, and branding to cans, bags, and pouches. High-speed systems support large-scale production, while print-and-apply options offer flexibility for private label and contract manufacturers.

Other Notable Sectors

Additional industries benefiting from labeling machinery include electronics, chemicals, logistics, and food processing. Each sector has unique requirements for durability, resistance (to heat, moisture, or chemicals), and regulatory compliance.

Choosing the Correct Labeling Machinery Manufacturer

To achieve the best results when purchasing labeling machinery, it’s critical to select a manufacturer that aligns with your specific operational needs, budget, and long-term growth plans. Our comprehensive directory of labeling machinery manufacturers allows you to:

- Compare detailed business profiles highlighting each manufacturer’s expertise, certifications (such as ISO or CE), and industry specializations.

- Access user reviews and case studies that showcase real-world performance, reliability, and customer satisfaction.

- Utilize our proprietary website previewer to quickly assess each company’s product range, technology focus, and service offerings.

- Submit inquiries or request quotes directly through integrated contact forms—streamlining the vendor selection process.

- Leverage our RFQ (Request for Quote) form to contact multiple labeling machinery suppliers with a single submission, saving time and ensuring competitive pricing.

- Request virtual or on-site demonstrations to see machinery in action and evaluate integration with your existing production line.

Are you ready to find the best labeling machinery manufacturer for your project? Visit our Labeling Machinery Manufacturer Directory.

Next Steps: Streamline Your Labeling Process

Labeling machinery is an essential investment for businesses seeking to increase efficiency, consistency, and compliance in packaging and production. As you research your options, consider all relevant factors—from machine type and application to support, scalability, and ROI. For more information, in-depth guides, and the latest industry trends, explore the following resources:

Have additional questions about labeling machinery selection, integration, or customization? Contact our team for personalized assistance and get started on enhancing your packaging operations today.

What are the main components of labeling machinery?

The main components of labeling machinery include the labeling applicator, conveyor system, labeling head, control system, and power source. Advanced machines may also feature integrated printers, inspection cameras, and automated label reel changers for enhanced efficiency and quality control.

What types of labeling machines are available?

Common types of labeling machines include pressure-sensitive labeling machines, sleeve labeling machines, hot melt labeling machines, cold glue labeling machines, print and apply labeling machines, RFID labeling machines, and specialty machines like wrap-around, top and bottom, and tamper-evident labelers.

What factors should be considered when selecting labeling machinery?

Key considerations include initial investment cost, maintenance and downtime needs, operator training, risk of labeling errors, scalability for future growth, and compatibility with existing packaging lines and software.

What are the benefits of using labeling machinery?

Labeling machinery provides precision and consistency, increased throughput, lower labor costs, improved compliance, greater flexibility, enhanced traceability, and reduced material waste and product rejects.

In which industries is labeling machinery commonly used?

Labeling machinery is widely used in the automotive, agriculture, aerospace, clothing, consumer goods, packaging, wine, medical, nutraceutical, pet food, and other notable sectors including electronics, chemicals, logistics, and food processing.

What are the advantages of print and apply labeling machines?

Print and apply labeling machines offer real-time variable data printing and automatic label application, making them ideal for operations requiring barcodes, batch numbers, expiration dates, and shipping information. They improve traceability, compliance, and labor efficiency in logistics and warehousing.

How can I choose the right labeling machinery manufacturer?

Choose a manufacturer by comparing expertise, certifications, user reviews, technology focus, and available support. Utilize directories to access business profiles, request quotes, and schedule demonstrations to evaluate how their solutions fit your operational needs.

Cardboard Tubes

Cardboard Tubes Carrying Cases

Carrying Cases Contract Packaging

Contract Packaging Corrugated Boxes

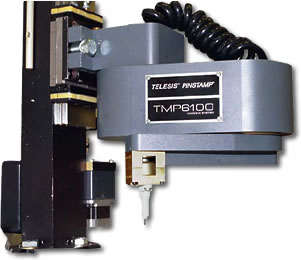

Corrugated Boxes Dot Peening Machines

Dot Peening Machines Labeling Machinery

Labeling Machinery Marking Machinery

Marking Machinery Packaging Equipment

Packaging Equipment Palletizers

Palletizers Plastic Bags

Plastic Bags Sewing Contractors

Sewing Contractors Tape Suppliers

Tape Suppliers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services