JN White is an ISO 9001:2015 and ITAR-certified manufacturer of labeling machinery, graphic overlays, and custom labels. We handle projects of a variety of sizes, and we have the expertise to translate what our customers need into high-quality, high-precision outcomes.

U.S. Tape & Label specializes in providing quality labeling equipment, automatic labeling, bar code labeling, labeling applicators, labeling systems and customized labelers. We offer the finest labeling machinery on the market today with a multitude of functions to fulfill all your labeling needs.

Since 1989, Label Mill has focused on label applicators and printer applicators. Label Mill has designed and built a full line of labeling solutions that have set new standards for simplicity of design, reliability, and ease of use. We have earned a reputation for developing custom solutions to meet the ever growing unique requirements for each individual customer and application.

Total solutions are our company goal. No matter whether you need flexible packaging, pressure-sensitive labels, or automatic labeling equipment, we have it all. We also offer customized service and support to all customers. We believe in offering the latest technology and service to all customers, and we even offer RFID services. You can learn more when you contact us today!

More Labeling Machine Manufacturers

Labeling machines are widely used in the manufacturing industry to label various products quickly and accurately. These machines come in different variations, each designed to meet specific labeling needs, and they consist of several components working together to ensure efficient labeling. In this article, we will explore the components, variations, considerations, benefits, and applications of labeling machines.

Components of Labeling Machines

A typical labeling machine consists of several components, including conveyors, labeling heads, control panels, print engines, sensors, and power sources. Conveyors transport products to the labeling station, where the labeling head applies the label onto the product. Control panels allow operators to configure machine settings and monitor the labeling process, while print engines are responsible for printing labels with relevant product information. Sensors are also crucial components that detect products on the conveyor and ensure accurate label placement. Finally, power sources such as electricity or compressed air are necessary to power the labeling machine.

Variations of Labeling Machines

There are various types of labeling machines, each designed to meet specific labeling requirements. These include pressure-sensitive labelers, sleeve labelers, print and apply labelers, wraparound labelers, front and back labelers, combination labelers, and rotary labelers. Pressure-sensitive labelers use pressure to apply labels onto the product, while sleeve labelers apply shrink sleeves onto containers. Print and apply labelers print and apply labels onto products, while wraparound labelers apply labels around the entire circumference of a product. Front and back labelers apply labels on both sides of a product, while combination labelers combine different types of labeling techniques. Finally, rotary labelers use a rotating carousel to apply labels onto products.

Considerations Regarding Labeling Machines

Despite the benefits of labeling machines, there are some considerations to keep in mind when using them. Initial costs can be high, especially for specialized labeling machines that require additional components. Maintenance requirements can also be significant, and downtime for repairs can be costly. Speed limitations can also affect the productivity of labeling machines, especially if they are not designed to handle high-speed labeling. Compatibility issues with different materials can also affect the quality of labeling, and environment restrictions can limit the use of labeling machines in certain industries.

Benefits of Labeling Machines

Despite the limitations, labeling machines provide significant benefits to manufacturing industries. One of the most significant advantages is increased productivity, as labeling machines can label products much faster than manual labeling. Consistent labeling accuracy is also crucial, ensuring that products are labeled correctly every time. Labeling machines also reduce labor costs by automating the labeling process, and they are flexible enough to handle a wide range of products, including irregularly shaped objects. Finally, labeling machines can enhance brand image by providing attractive and professional-looking labels for products.

Applications of Labeling Machines

Labeling machines are used in various industries, including:

Food and Beverage Industry

In the food and beverage industry, labeling machines are used to label products with nutritional information, ingredient lists, and expiration dates.

Pharmaceutical Industry

In the pharmaceutical industry, labeling machines are used to label drug containers with information on dosages, expiration dates, and safety information.

Cosmetics and Personal Care Industry

In the cosmetics and personal care industry, labeling machines are used to label products with ingredient lists, safety warnings, and branding.

Chemical Industry

In the chemical industry, labeling machines are used to label hazardous chemicals with safety warnings and handling instructions.

Automotive Industry

In the automotive industry, labeling machines are used to label car parts with identification codes and safety information.

Consumer Goods Industry

In the consumer goods industry, labeling machines are used to label products with branding and pricing information.

Logistics and Warehousing

Labeling machines are used to label shipping containers, pallets, and cartons with information such as product codes, SKUs, barcodes, and shipping labels.

Electronics

Labeling machines are used to label electronic components with identifying information such as part numbers, manufacturing dates, and serial numbers.

Agriculture

Labeling machines are used to label fruits and vegetables with information such as variety, grade, and country of origin.

Textile

Labeling machines are used to label clothing items with information such as size, care instructions, and fabric content.

Industrial Manufacturing

Labeling machines are used to label industrial products with information such as model numbers, manufacturing dates, and safety warnings.

Medical Devices

Labeling machines are used to label medical devices with information such as product codes, manufacturing dates, and usage instructions.

Retail

Labeling machines are used in retail stores to print and apply price labels onto products, or to create promotional labels for sales and discounts.

Military and Aerospace

Labeling machines are used to label military and aerospace equipment with identifying information such as part numbers, serial numbers, and inspection dates.

Choosing the Right Labeling Machine Supplier

To ensure you have the most beneficial outcome when purchasing a labeling machine from a labeling machine supplier, it is important to compare several companies using our directory of labeling machine suppliers. Each labeling machine supplier has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the supplier for more information or to request a quote. Review each labeling machine business website using our proprietary website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple labeling machine companies with the same form.

Cardboard Tubes

Cardboard Tubes Carrying Cases

Carrying Cases Contract Packaging

Contract Packaging Corrugated Boxes

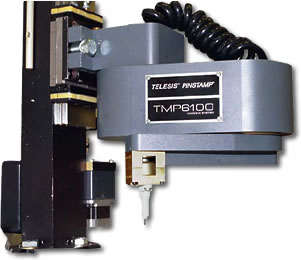

Corrugated Boxes Dot Peening Machines

Dot Peening Machines Labeling Machinery

Labeling Machinery Marking Machinery

Marking Machinery Packaging Equipment

Packaging Equipment Palletizers

Palletizers Plastic Bags

Plastic Bags Sewing Contractors

Sewing Contractors Tape Suppliers

Tape Suppliers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services