JN White is an ISO 9001:2015 and ITAR-certified manufacturer of labeling machinery, graphic overlays, and custom labels. We handle projects of a variety of sizes, and we have the expertise to translate what our customers need into high-quality, high-precision outcomes.

BW Packaging is a leading label application manufacturer creating equipment for automotive, food & beverage, commercial, consumer, and pharmaceutical industries, to name a few. We have a dependable support program, from installation to maintenance and replacement parts. We partner with our customers through the entire process, from planning to production. Contact us today.

We offer top of the line label machines to suit the needs of our customers. We are the largest manufacturer of labeling equipment in the country, and we have everything our customers can think of. We can customize our products to suit your unique needs and requirements. We believe in offering the best technologies and techniques to all customers. Contact us to learn more!

We offer labelers and labeling machinery: hot melt glue labeling systems, pressure sensitive labeling machines and shrink sleeve labeling machines. Since 1989, Accutek Packaging Equipment has designed/manufactured bottling and packaging machinery. We can customize to fit any application.

Label-Aire has been producing top of the line label machines for nearly fifty years. We offer the easiest, most effective labeling solutions around and we have dependable customer service representatives and a highly skilled team of technicians. We pride ourselves on being the best in terms of quality and service. Your satisfaction is guaranteed, so put us to work for you today!

More Labeler Manufacturers

Comprehensive Guide to Industrial Labeling Systems and Machines

In today’s fast-paced manufacturing and distribution environments, efficient labeling systems are essential for traceability, regulatory compliance, branding, and operational efficiency. A modern labeling system can encompass a complete automated solution or consist of individual components such as industrial label printers, automatic label dispensers, or high-speed label applicators. Choosing the right equipment is crucial for streamlining workflow, reducing errors, and improving product presentation.

What Is a Labeling System and How Does It Work?

A labeling system integrates multiple components to automate the process of printing, dispensing, and applying labels onto products or packaging. These systems may include:

- Label printers – Devices designed to print information, graphics, barcodes, or QR codes onto various label substrates.

- Label dispensers – Mechanisms that separate and present each label for application, often removing the backing for adhesive labels.

- Label applicators – Machines that physically affix the label to the product using methods such as tamp, blow-on, or wipe-on techniques.

- Integrated controls and sensors – For precise product detection, label alignment, and quality assurance.

Labeling systems are highly customizable to meet the needs of diverse industries, from pharmaceuticals and food production to automotive and electronics. Are you wondering which labeling solution is best for your business? Explore different types of labeling systems and discover which configuration aligns with your production requirements.

Industries and Applications for Labeling Machines

Labeling technology is indispensable in a wide range of sectors. Here are some of the key industries that rely on label machines and the specific applications:

- Pharmaceutical labeling – Ensures regulatory compliance, serialization, and traceability for medicines and medical devices.

- Food and beverage labeling – Provides nutritional information, expiration dates, allergen warnings, and branding on packaging.

- Cosmetic labeling – Delivers product identification, batch numbers, and decorative designs for retail appeal.

- Automotive and aerospace labeling – Marks components with safety information, serial numbers, and logistics details for quality control and inventory management.

- Electronics labeling – Enables barcoding, warranty tracking, and compliance marking for circuit boards, devices, and packaging.

- Logistics, shipping, and warehousing – Facilitates efficient inventory tracking, shipping management, and supply chain visibility.

- Agricultural and horticultural labeling – Supports plant identification, traceability, and regulatory compliance.

- Waste treatment and environmental labeling – Ensures proper waste identification and hazardous material compliance.

Whether you need industrial labeling for large-scale manufacturing or simple desktop labelers for small businesses, choosing the right machine is vital. What are your specific labeling needs? Browse available label machines by industry, application, or capacity to find your best fit.

Types of Labeling Machines: From Manual to Fully Automatic

The range of labeling machines available on the market accommodates everything from low-volume, hand-operated devices to highly sophisticated, floor-mounted units for high-speed, automated production lines. Understanding the types of machines will help you select the optimal solution for your organization:

- Handheld and manual labelers – Ideal for office organization, small batch runs, or personal projects. They offer portability and ease of use, but limited speed.

- Bench-top and semi-automatic labelers – Larger and more adjustable, these systems suit retail, commercial, or mid-volume production environments. They provide greater precision and throughput than manual models.

- Industrial labeling machines – Robust, floor-mounted solutions designed for continuous operation in manufacturing plants. These machines handle high production rates with exceptional accuracy, support various label types, and offer integration with existing conveyor and packaging lines.

Labeling machines may be configured for:

- Vertical or horizontal wrap-around application

- Front, top, back, or bottom label placement

- Inline or rotary systems for continuous throughput

Curious about which configuration matches your production flow? Learn about different labeling machine setups and how they can improve your efficiency.

Label Printing: Technologies and Material Compatibility

Label creation begins with the label printer. While standard household printers may be suitable for low-volume jobs, specialized industrial label printers are engineered to handle a diverse array of materials and demanding print requirements. Popular printing technologies include:

- Thermal transfer printing – Delivers durable, high-resolution labels on synthetic, paper, or specialty substrates, making it ideal for industrial and harsh environments.

- Direct thermal printing – Suitable for short-term labeling such as shipping and perishable food products, as it doesn’t require ink or toner.

- Inkjet and laser printing – Provides vibrant, full-color labels for branding and retail display.

- Digital printing – Enables on-demand, variable data, and short-run label production with minimal setup time.

Materials that can be labeled include:

- Metals (aluminum, stainless steel)

- Glass (bottles, jars, laboratory glassware)

- Plastics (containers, packaging, automotive parts)

- Papers and cardboards (shipping labels, product tags)

- Foils and flexible films

- Textiles and fibers

Labels can be printed, dyed, engraved, or embossed to meet a variety of durability, readability, and aesthetic requirements. Need help choosing the right printing technology? Explore label printer options for your unique materials and label formats.

Label Dispensing and Application: Methods and Automation Levels

Once labels are printed, label dispensers and applicators prepare and affix them to target surfaces. The dispensing process involves presenting each label for easy pickup or automated application, often removing backing material for adhesive labels. Label applicators then utilize one of several application methods:

- Tamp (touch-on) application – The applicator physically presses or taps the label onto the product with precise pressure control, ideal for uniform surfaces.

- Blow-on (air application) – Uses a controlled burst of air to transfer the label onto delicate or irregularly shaped products without contact.

- Wipe-on application – The label is wrapped or wiped onto the product, ensuring secure adhesion on round containers, bottles, or uneven surfaces.

Manual application is still used in low-volume or specialty settings, but fully automated labelers offer superior speed, consistency, and accuracy—critical for high-throughput operations.

Label Design Considerations: Size, Material, and Adhesion

Effective labeling starts with understanding your unique requirements. Before printing, dispensing, or application, carefully consider:

- Label size and shape – Must fit the product surface and accommodate all required information.

- Material compatibility – The label material (paper, film, synthetic, metal) must be suitable for the product and environment (e.g., heat, moisture, abrasion resistance).

- Adhesive selection – The glue or fastening mechanism must bond securely to the substrate, whether it’s glass, plastic, metal, or cardboard.

- Durability requirements – Consider resistance to chemicals, UV light, water, and temperature extremes.

Are you unsure which label materials or adhesives are best for your product? Read our material selection guide or contact our labeling experts for tailored recommendations.

Labeling for Compliance and Branding: Why It Matters

Labeling isn’t just about product identification—it's a legal and commercial necessity. Many industries face strict requirements regarding what must appear on product labels. Regulatory agencies such as the FDA, OSHA, and international bodies mandate specific disclosures for safety, traceability, and consumer protection. Examples include:

- Ingredient and allergen lists for food products

- Dosage instructions and batch codes for pharmaceuticals

- Hazard warnings and handling instructions for chemicals

- CE, UL, or RoHS marks for electronics and machinery

Beyond compliance, labels play a vital role in branding, consumer engagement, and shelf appeal. High-quality, visually appealing labels can differentiate your products and foster customer loyalty. Looking to improve your brand image? Discover label applicator solutions that optimize both compliance and marketing effectiveness.

Choosing the Right Labeling System: Key Decision Factors

Selecting the best labeling machine or system involves evaluating several critical factors:

- Production volume and speed – Ensure your equipment matches current and anticipated throughput requirements.

- Label type and format – Choose machinery compatible with your preferred label shapes, sizes, and materials.

- Integration with existing lines – Select systems that can be seamlessly added to your conveyors, fillers, or packaging equipment.

- Automation level – Consider manual, semi-automatic, or fully automatic solutions based on labor availability and ROI.

- Budget and total cost of ownership – Evaluate both upfront investment and ongoing maintenance, supplies, and consumables.

- Ease of use and operator training – Look for intuitive controls, quick setup, and reliable technical support.

- Space constraints and footprint – Choose systems that fit your available workspace.

Not sure where to start? Use our labeling system selector tool to compare options based on your specific requirements.

Benefits of Automated Labeling Systems

Investing in modern labeling equipment provides measurable advantages, including:

- Increased productivity – Reduce manual labor and labeling errors, enabling higher throughput and consistent results.

- Enhanced accuracy and quality – Ensure correct label placement, data integrity, and professional appearance.

- Regulatory compliance – Meet legal and industry-specific labeling standards to avoid costly penalties and recalls.

- Improved traceability and inventory control – Track products through barcoding and serialization for better supply chain management.

- Brand consistency – Deliver uniform, attractive labels that reinforce your brand image and value proposition.

- Scalability and flexibility – Adapt quickly to new SKUs, packaging formats, or regulatory changes.

Ready to automate your labeling process? Request a quote or schedule a demonstration to see how the latest labeling solutions can transform your business.

Frequently Asked Questions About Labeling Machines and Systems

- How do I choose between manual, semi-automatic, and fully automated labelers? Consider your production scale, labor costs, and need for accuracy. Automated systems excel in high-volume, repetitive environments, while manual or semi-automatic models may suit smaller operations.

- What are the most durable label materials for harsh environments? Synthetic films, polyester, and metal labels offer superior resistance to chemicals, water, and abrasion. Consult your supplier for application-specific recommendations.

- Can labeling machines handle unusual shapes or small products? Yes—many advanced systems feature adjustable applicators and smart sensors for precise labeling on bottles, vials, tubes, or irregularly shaped items.

- How can I ensure compliance with industry regulations? Work with experienced labeling solution providers who understand FDA, OSHA, or international standards relevant to your sector.

- What is the typical ROI for investing in automated labeling machinery? Most businesses see a return within one to three years thanks to reduced labor, fewer errors, increased speed, and lower compliance risk.

Next Steps: Optimize Your Labeling Workflow

Optimizing your labeling process is a strategic investment in efficiency, compliance, and brand value. Whether you are upgrading from manual labeling to automation or expanding your existing production line, the right equipment makes a measurable difference.

Ready to take the next step?

- Explore leading labeling systems for your industry.

- Compare label machines by type, speed, and compatibility.

- Find the right label applicators for your packaging needs.

- Contact labeling experts for a personalized consultation.

Explore in-depth resources, request product demos, and read customer success stories at labeling-machinery.net. Empower your business with advanced industrial labeling solutions and elevate your products with professional, reliable, and compliant labeling systems.

Cardboard Tubes

Cardboard Tubes Carrying Cases

Carrying Cases Contract Packaging

Contract Packaging Corrugated Boxes

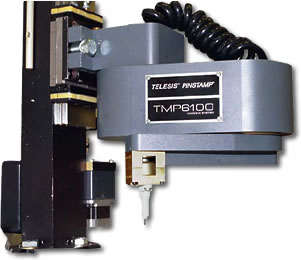

Corrugated Boxes Dot Peening Machines

Dot Peening Machines Labeling Machinery

Labeling Machinery Marking Machinery

Marking Machinery Packaging Equipment

Packaging Equipment Palletizers

Palletizers Plastic Bags

Plastic Bags Sewing Contractors

Sewing Contractors Tape Suppliers

Tape Suppliers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services