JN White is an ISO 9001:2015 and ITAR-certified manufacturer of labeling machinery, graphic overlays, and custom labels. We handle projects of a variety of sizes, and we have the expertise to translate what our customers need into high-quality, high-precision outcomes.

BW Packaging is a leading label application manufacturer creating equipment for automotive, food & beverage, commercial, consumer, and pharmaceutical industries, to name a few. We have a dependable support program, from installation to maintenance and replacement parts. We partner with our customers through the entire process, from planning to production. Contact us today.

We offer top of the line label machines to suit the needs of our customers. We are the largest manufacturer of labeling equipment in the country, and we have everything our customers can think of. We can customize our products to suit your unique needs and requirements. We believe in offering the best technologies and techniques to all customers. Contact us to learn more!

We offer labelers and labeling machinery: hot melt glue labeling systems, pressure sensitive labeling machines and shrink sleeve labeling machines. Since 1989, Accutek Packaging Equipment has designed/manufactured bottling and packaging machinery. We can customize to fit any application.

Label-Aire has been producing top of the line label machines for nearly fifty years. We offer the easiest, most effective labeling solutions around and we have dependable customer service representatives and a highly skilled team of technicians. We pride ourselves on being the best in terms of quality and service. Your satisfaction is guaranteed, so put us to work for you today!

More Label Applicator Manufacturers

Label Applicators: Essential Automation in Product Labeling

A label applicator, also known as a label dispenser or automatic labeling machine, is an industrial device engineered to streamline and automate the process of applying labels to products, packages, or containers. By eliminating manual labeling, these machines greatly improve efficiency, accuracy, and consistency across high-volume production lines. In today’s competitive landscape, labeling machines have become indispensable for companies seeking to boost productivity, reduce labor costs, and maintain compliance with regulatory requirements.

What is a Label Applicator?

At its core, a label applicator is a type of automated or semi-automated machinery designed to dispense, position, and adhere labels onto products or packaging surfaces. These machines are available in a variety of configurations, including manual, semi-automatic, and fully automatic systems, to accommodate the diverse needs of different industries. Label applicators are a key component in modern labeling systems, providing the speed and precision necessary for mass production environments.

Industries That Rely on Label Applicators

Label applicators play a crucial role in a wide range of industries where accurate and rapid labeling is essential for operational success. Some of the most notable sectors utilizing industrial labeling solutions include:

- Manufacturing – For product identification, tracking, and compliance labeling in automotive, electronics, and consumer goods.

- Shipping & Logistics – For applying address labels, barcodes, and tracking information on parcels and freight.

- Pharmaceutical & Healthcare – For ensuring drug traceability, patient safety, and regulatory compliance by labeling medications, medical devices, and packaging.

- Food & Beverage – For nutritional facts, expiration dates, allergen warnings, and branding on bottles, cans, and cartons.

- Retail & Pricing – For price tags, promotional stickers, and inventory management in stores and distribution centers.

- Packaging – For branding, product information, and compliance labeling on primary and secondary packaging materials.

Common Labeling Applications and Use Cases

Modern label applicators support a wide variety of labeling applications, including but not limited to:

- Product Identification: Barcodes, QR codes, and serial numbers for inventory and asset tracking.

- Regulatory & Compliance Labeling: Ingredient lists, allergen statements, warning labels, and certification marks.

- Shipping & Handling: Address labels, handling instructions, and tracking information for logistics.

- Branding & Marketing: Custom labels for logos, product names, and promotional messages.

- Instructional & Informational Labels: Assembly instructions, usage guidelines, and safety protocols.

- Promotional & Tamper-Evident Labels: Security seals, coupons, and limited-time offers.

Labels are critical not only for compliance but also for customer experience. For example, clear nutritional information on food packaging, warning labels on hazardous materials, and easy-to-read barcodes for point-of-sale systems are all made possible by reliable label applicator machines.

Types of Label Applicators: Choosing the Right Solution

The label applicator market encompasses a variety of machine types, each engineered for specific labeling tasks and production environments. Understanding the differences between these applicators can help you select the ideal solution for your operation.

1. Air-Blow Label Applicators

Air-blow applicators utilize a vacuum grid to hold labels in place and deploy pressurized air jets to affix the label precisely onto the product as it passes beneath the grid. This non-contact labeling method is highly efficient, extremely accurate, and suitable for high-speed production lines where minimal physical contact with the product is required. Industries such as electronics manufacturing and food processing often prefer air-blow applicators for their speed and gentle application.

2. Tamp-Blow Label Applicators

Tamp-blow applicators combine tamping and blowing actions to apply labels. The label is held by a vacuum pad, then lightly tamped onto the product’s surface. A burst of air ensures adhesion. Some advanced tamp-blow systems offer dual-action functionality, enabling the simultaneous application of two labels (e.g., front and back labeling), making them ideal for complex packaging and pharmaceutical labeling requirements.

3. Wipe-On Label Applicators

Wipe-on applicators apply labels by mechanically wiping the label onto the product as it moves along a conveyor belt. This method ensures the label adheres smoothly, even to irregular or curved surfaces. Wipe-on applicators are well-suited for corner-wrapping, labeling round bottles, or applying large-format labels to cartons and cases.

4. Printer-Applicators

Printer-applicators combine on-demand label printing with automatic application. These smart devices print variable data—such as batch numbers, expiration dates, or unique barcodes—immediately before applying the label. Printer-applicators are invaluable in environments that require high levels of product traceability and real-time data updates, such as pharmaceuticals, food production, and logistics.

5. Manual and Semi-Automatic Label Dispensers

Manual or pressure-based label dispensers are designed for low-volume or specialty labeling tasks. While not fully automated, these tools increase efficiency and reduce waste in office settings, small-batch manufacturing, and environments where flexibility is key. Semi-automatic dispensers bridge the gap between manual and automated systems, offering speed improvements while still requiring some operator involvement.

How to Select the Best Label Applicator for Your Business

Choosing the right label applicator is crucial for optimizing your production workflow and ensuring consistent label quality. Here are key decision factors to consider:

- Production Volume: High-speed automatic machines are ideal for large-scale operations, while manual dispensers suit smaller businesses.

- Label & Product Specifications: Consider label size, shape, material, and the surface characteristics of the items being labeled.

- Integration with Existing Systems: Ensure compatibility with your current production line, conveyor systems, or packaging equipment.

- Application Accuracy: For products with tight placement tolerances, choose applicators with advanced sensors and controls.

- Budget Constraints: Balance upfront investment with long-term savings from increased productivity and reduced labor costs.

- Regulatory Requirements: Industries like pharmaceuticals and food require machines certified for safety and traceability standards.

- Ease of Use & Maintenance: Opt for user-friendly interfaces and machines with minimal maintenance needs to reduce downtime.

Need help selecting the right labeling solution? Ask yourself: What is my expected production volume? Do I need integration with printers or other automation systems? Are there specific industry compliance requirements I must meet? Explore our guide to labeling machines for more detailed comparisons and recommendations.

Key Benefits of Automated Label Applicators

Adopting an automated label applicator brings significant advantages, including:

- Increased Throughput: Label thousands of products per hour with minimal manual intervention.

- Enhanced Label Consistency: Achieve perfect placement and uniform appearance, reducing mislabeling errors.

- Reduced Labor Costs: Minimize manual labor, freeing up staff for higher-value tasks.

- Regulatory Compliance: Meet industry standards for traceability and safety labeling without error.

- Scalability: Easily adapt to new product lines or higher production volumes with modular systems.

- Operational Data & Reporting: Advanced machines offer production analytics and label verification for quality control.

- Waste Minimization: Reduce label and packaging waste through precise, error-free application.

Label Applicator Use Cases: Industry Examples

- Food Manufacturing: Apply nutritional facts, ingredient lists, and expiration dates to cans, bottles, and flexible packages at high speed.

- Pharmaceuticals: Ensure tamper-evident and serialized labeling for medical vials, cartons, and blister packs to comply with FDA regulations.

- Cosmetics & Personal Care: Accurately label bottles, tubes, and jars with branding and regulatory information.

- Automotive: Attach barcodes and part numbers to components for inventory management and recall tracking.

- Warehousing: Apply shipping and inventory labels to pallets, cases, and totes for efficient order fulfillment.

- Retail: Affix pricing stickers and promotional labels to products for in-store display and inventory control.

Frequently Asked Questions About Label Applicators

What are the main types of labels compatible with applicator machines?

Label applicators can handle a wide array of label materials and formats, including pressure-sensitive labels, thermal transfer and direct thermal labels, RFID tags, clear labels, and specialty security or tamper-evident labels. Choosing the correct label stock is vital for optimal adhesion and legibility.

How do I maintain and troubleshoot a label applicator?

Regular maintenance—including cleaning rollers, checking sensors, and inspecting label feed mechanisms—ensures consistent performance and reduces downtime. Manufacturers typically provide troubleshooting guides, but prompt attention to jams, misfeeds, or adhesive buildup is key for optimal operation.

Can label applicators handle variable-height or irregularly shaped products?

Yes, many modern applicators are equipped with adjustable applicator heads, sensors, and flexible mounting systems to accommodate products of varying shapes and sizes. For unique labeling challenges, consult with a labeling equipment specialist to identify the best custom solution.

What is the ROI of investing in an automated label applicator?

ROI is typically realized through reduced labor expenses, fewer labeling errors, improved production speed, and enhanced compliance. Many manufacturers report full payback within months due to increased throughput and higher product quality.

How to Compare Label Applicator Manufacturers and Suppliers

When researching label applicator suppliers or manufacturers, consider:

- Reputation and reliability: Look for established brands with positive reviews and proven track records.

- Customization options: Choose providers who offer tailored solutions for your specific products and workflows.

- After-sales support: Assess the availability of training, technical support, and spare parts.

- Technology integration: Seek out machines that seamlessly connect with your ERP, MES, or warehouse management systems.

- Compliance and certifications: Ensure machines meet regulatory standards for your industry, such as FDA or GMP requirements.

If you’re ready to compare pricing or get recommendations for your application, ask yourself: What features are most important for my operation—speed, flexibility, or integration? Would I benefit from a modular system that can grow with my business?

Label Applicator Trends and Innovations

The labeling equipment industry continues to evolve rapidly, with advancements in automation, connectivity, and machine learning. Some notable trends include:

- Smart Sensors & IoT Integration: Real-time monitoring of label placement quality and predictive maintenance alerts.

- Machine Vision Systems: Automated verification of label accuracy and barcode readability.

- Tool-less Changeovers: Quick and easy adjustments to accommodate different products or label sizes, minimizing downtime.

- Modular Machine Design: Flexible systems that allow for the easy addition of labeling heads, printers, or applicator modules as needs change.

- Sustainable Labeling Solutions: Eco-friendly adhesives, recyclable label materials, and energy-efficient machinery to support green initiatives.

Getting Started: How to Implement a Label Applicator System

Looking to automate your labeling process?

- Assess your labeling requirements – Define production volume, product types, label materials, and compliance needs.

- Consult with labeling specialists – Work with experts to select the most appropriate machine type and configuration. Start your research here.

- Plan for integration – Ensure smooth communication with existing packaging lines, printers, and data management systems.

- Train your staff – Provide comprehensive training on setup, operation, and maintenance to maximize uptime and efficiency.

- Monitor and optimize – Use machine analytics and reporting tools to continuously improve labeling performance and reduce waste.

If you’re unsure where to begin, consider reaching out to leading labeling machine manufacturers for consultations and product demonstrations. Many providers will conduct site audits to recommend the best solutions for your specific production environment.

Conclusion: Why Invest in a Label Applicator?

Automated label applicators have become a cornerstone of modern manufacturing, packaging, and logistics operations. By ensuring rapid, accurate, and consistent label application, these machines help businesses comply with regulations, enhance their brand image, and streamline their operations. With a wide variety of machine types, features, and integration options available, there’s a label applicator solution for every business need—from startups to large-scale enterprises.

Ready to take the next step? Explore our directory of top labeling equipment suppliers or request a quote to see how automated label applicators can transform your production line and drive ROI.

Cardboard Tubes

Cardboard Tubes Carrying Cases

Carrying Cases Contract Packaging

Contract Packaging Corrugated Boxes

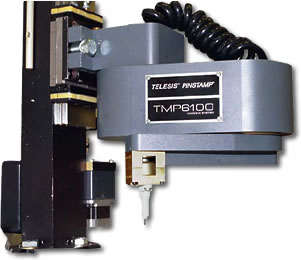

Corrugated Boxes Dot Peening Machines

Dot Peening Machines Labeling Machinery

Labeling Machinery Marking Machinery

Marking Machinery Packaging Equipment

Packaging Equipment Palletizers

Palletizers Plastic Bags

Plastic Bags Sewing Contractors

Sewing Contractors Tape Suppliers

Tape Suppliers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services